Source: 本站 | Date of issue: 2021-07-14 14:48:38 | Views: 15163

1. Contact fatigue failure. Under the action of high contact stress, after many stress cycles, pits will be generated in the local area of the working surface, which will increase the noise, vibration, temperature and wear of the bearing during operat…

The use of various mechanical equipment in our lives is very common, and in the production of these mechanical equipment, the bearing is an i…

The quality of the one-way bearing directly affects the length of the bearing time, so the quality of the steel must be screened when selecti…

1. Contact fatigue failure. Under the action of high contact stress, after many stress cycles, pits will be generated in the local area of th…

The installation of the bearing directly affects the accuracy, life and performance. Therefore, the design and assembly of the bearing should…

The centripetal needle roller and cage assembly is an independent bearing element, in which each need…

Thrust needle roller bearings are composed of thrust retaining components with needle rollers or cyli…

Tapered roller bearings are mainly suitable for bearing combined radial and axial loads based on radi…

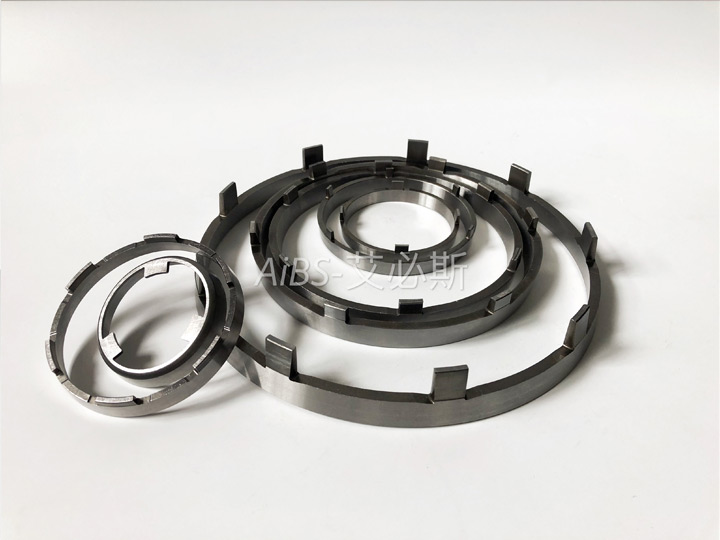

The synchronizer middle ring is a single part and an important part of the synchronizer of the automo…

Cylindrical roller bearings are usually guided by the two ribs of a bearing ring, and the cage, rolle…

The bushing can choose different structures according to the assembly and use occasions, with ribs, o…

Drawn cup needle roller bearings have a variety of structures such as perforated type and sealed type…

Deep groove ball bearings have a variety of optional structures, including open bearings, grease-fill…